KBR’s PureSAF Technology Can Fully Replace Jet Fuel and Utilize Carbon Dioxide

With the demand expected to exceed 75 billion metric tons of sustainable aviation fuel (SAF) per year by 2040, a massive supply challenge is emerging for the aviation industry. How can the aviation sector reduce its environmental footprint and move towards carbon neutrality, without curbing growth? KBR’s unique sustainable aviation fuel (SAF) technology, PureSAF ℠, is one solution.

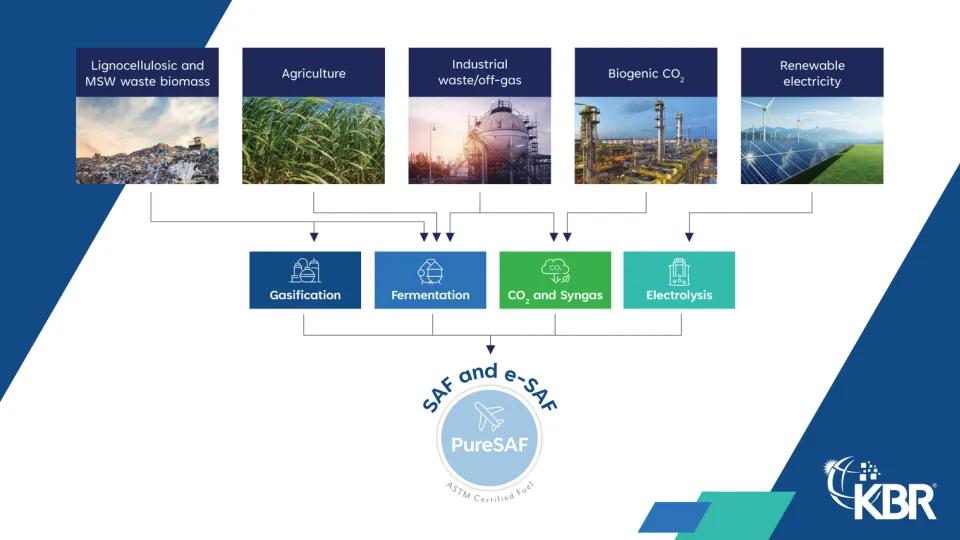

Unmatched feedstock flexibility

KBR offers ASTM-certified (American Society for Testing and Materials) SAF technology through the alcohol-to-jet pathway, which processes multiple feedstocks like bioethanol, syngas, carbon dioxide, syngas and hydrogen. These feedstocks, from industrial sites, can be further converted to SAF, diesel, and gasoline.

“Multiple pathways for SAF production have been identified, utilizing a variety of feedstock sources. KBR’s PureSAF technology is an innovative process that produces a fully fungible military grade jet fuel, validated by the U.S. Defense Advanced Research Projects Agency (DARPA), at low cost and industrial scale. This, along with the ability to utilize CO2 and syngas, makes it a differentiated offering in the global SAF landscape,” said Hari Ravindran, SVP & Global Head, KBR Technology Solutions.

Equivalent replacement for fossil jet fuel

Developed by Swedish Biofuels AB and globally licensed exclusively by KBR, this advanced SAF technology contains the same distribution and types of hydrocarbons as those found in petroleum-derived aviation turbine fuels. The resulting SAF is a fully identical to fossil jet fuel with the same or, in some cases, better physical-chemical properties.

PureSAF’s feed flexibility significantly improves the overall cost competitiveness compared to alternate offerings, which require separate technologies for conversion of ethanol and gases.

Commercialization underway

In an effort to make farm-to-flight jet fuel a tangible reality, KBR’s PureSAF technology platform has been selected by Renewable Developments Australia (RDA), in collaboration with Virgin Australia and Qatar Airways to establish a SAF production facility. Here, bioethanol derived from sugarcane grown onsite will be converted to 100% SAF utilizing the ethanol-to-jet pathway.

In addition, KBR is developing a SAF facility at Pittsburgh International Terminal to drive energy innovation based on KBR’s PureSAF technology. This will not only help airline partners to secure SAF effectively but also meet the SAF demands of Pittsburgh International and its nearby airports.

Last year, within the Liepaja Special Economic Zone (LSEZ), KBR signed an MOU with NorSAF (formerly GI Terminal) to support the production of renewable SAF, gasoline and diesel at their terminal site in Liepaja, Latvia.

PureSAF is a flexible and sustainable solution

By 2050, replacing fossil jet fuels with SAF is projected to reduce global greenhouse gas emissions by 2.5%. Many governments and airlines have made phased commitments to reduce emissions and predominantly via SAF. As a result, stakeholders, including governments, airlines, developers, and investors, are evaluating and selecting the most suitable pathways for SAF production. With its feedstock flexibility and ability to fully replace fossil jet fuel meeting the ASTM specification, PureSAF is poised to make a major contribution towards decarbonizing the aviation industry.